SPOILER ALERT!

Exactly How To Figure Out The Very Best Tunnel Pasteurizer For Your Company Needs

Article Composed By-Borg Harvey

When picking the ideal Tunnel pasteurizer for your company, you face a critical choice that can impact your manufacturing efficiency substantially. The procedure entails weighing different variables like size, capacity, temperature level control, and upkeep needs. It's not just about the preliminary purchase; it's additionally about lasting functional expenses and support. Comprehending the subtleties of different Tunnel pasteurizer kinds and their viability for your specific requirements is paramount. Your choice will certainly play a crucial duty in ensuring the quality and safety of your products while optimizing your manufacturing processes.

## Key Elements to Think About

When selecting a passage pasteurizer for your service, it's essential to take into consideration a number of key aspects that will impact the performance and effectiveness of your pasteurization procedure.

First of all, analyze the size and ability needs of your assembly line. Make certain the Tunnel pasteurizer you select can manage the volume of products you need to process to prevent traffic jams or delays in manufacturing.

Secondly, consider the heating and cooling down capabilities of the pasteurizer. The temperature level control accuracy is essential to ensure that your items are pasteurized efficiently without jeopardizing high quality. Search for a tunnel pasteurizer that uses precise temperature level tracking and adjustment attributes to fulfill your details pasteurization requirements.

Another vital variable to think about is the footprint and layout of the Tunnel pasteurizer. Make sure the tools fits well within your production center and can be conveniently incorporated right into your existing line without significant alterations. Additionally, assess the maintenance demands and the schedule of technological support for the pasteurizer to guarantee smooth procedures and minimal downtime.

## Types of Tunnel Pasteurizers

To better recognize the diverse alternatives available out there, it is necessary to explore the numerous types of Tunnel pasteurizers matched for various production demands and procedures.

One typical type is the continuous Tunnel pasteurizer, perfect for high-volume manufacturing with consistent warm treatment. If you have differing manufacturing speeds, a modular Tunnel pasteurizer might be the most effective fit as it permits adaptability in line configurations.

For smaller businesses, a compact Tunnel pasteurizer could be the appropriate choice, providing space efficiency without endangering on pasteurization high quality. If your items need particular treatment zones, an adjustable Tunnel pasteurizer might be one of the most suitable option, allowing modification of warm direct exposure degrees.

Furthermore, Tunnel pasteurizers can be classified based on heating techniques such as water immersion, steam shot, or hot air, each offering one-of-a-kind benefits depending on the product being refined. Comprehending these kinds will certainly help you pick the Tunnel pasteurizer that aligns best with your organization needs.

## Budgeting and Cost Evaluation

Thinking about the monetary aspects of buying a passage pasteurizer is an essential step in your service decision-making procedure. When https://www.theceomagazine.com/executive-interviews/food-beverage/bennett-neo/ for a passage pasteurizer, think about not just the first purchase price but likewise continuous expenses such as upkeep, energy consumption, and possible upgrades.

Conduct a comprehensive cost evaluation to figure out the overall expense of ownership over the lifespan of the devices. Look for Tunnel pasteurizers that offer an equilibrium between ahead of time costs and long-term financial savings via energy effectiveness and lowered maintenance demands.

Bear in mind to consider any extra expenses such as installation, training, and prospective downtime during application. Compare quotes from various distributors and consider negotiating for a far better bargain or exploring funding options to alleviate the monetary problem.

## Verdict

In conclusion, selecting the appropriate Tunnel pasteurizer for your business calls for careful factor to consider of variables such as dimension, capability, heating and cooling down abilities, maintenance needs, and technological support schedule. Evaluate various kinds of pasteurizers to locate the most effective suitable for your manufacturing demands and budget restrictions. Conduct https://www.deccanherald.com/business/paper-boat-juicing-recipe-right-2072557 detailed price evaluation to identify the complete possession price, including installation and potential downtime costs. With these factors in mind, you can make an informed decision that will certainly benefit your service in the future.

When picking the ideal Tunnel pasteurizer for your company, you face a critical choice that can impact your manufacturing efficiency substantially. The procedure entails weighing different variables like size, capacity, temperature level control, and upkeep needs. It's not just about the preliminary purchase; it's additionally about lasting functional expenses and support. Comprehending the subtleties of different Tunnel pasteurizer kinds and their viability for your specific requirements is paramount. Your choice will certainly play a crucial duty in ensuring the quality and safety of your products while optimizing your manufacturing processes.

## Key Elements to Think About

When selecting a passage pasteurizer for your service, it's essential to take into consideration a number of key aspects that will impact the performance and effectiveness of your pasteurization procedure.

First of all, analyze the size and ability needs of your assembly line. Make certain the Tunnel pasteurizer you select can manage the volume of products you need to process to prevent traffic jams or delays in manufacturing.

Secondly, consider the heating and cooling down capabilities of the pasteurizer. The temperature level control accuracy is essential to ensure that your items are pasteurized efficiently without jeopardizing high quality. Search for a tunnel pasteurizer that uses precise temperature level tracking and adjustment attributes to fulfill your details pasteurization requirements.

Another vital variable to think about is the footprint and layout of the Tunnel pasteurizer. Make sure the tools fits well within your production center and can be conveniently incorporated right into your existing line without significant alterations. Additionally, assess the maintenance demands and the schedule of technological support for the pasteurizer to guarantee smooth procedures and minimal downtime.

## Types of Tunnel Pasteurizers

To better recognize the diverse alternatives available out there, it is necessary to explore the numerous types of Tunnel pasteurizers matched for various production demands and procedures.

One typical type is the continuous Tunnel pasteurizer, perfect for high-volume manufacturing with consistent warm treatment. If you have differing manufacturing speeds, a modular Tunnel pasteurizer might be the most effective fit as it permits adaptability in line configurations.

For smaller businesses, a compact Tunnel pasteurizer could be the appropriate choice, providing space efficiency without endangering on pasteurization high quality. If your items need particular treatment zones, an adjustable Tunnel pasteurizer might be one of the most suitable option, allowing modification of warm direct exposure degrees.

Furthermore, Tunnel pasteurizers can be classified based on heating techniques such as water immersion, steam shot, or hot air, each offering one-of-a-kind benefits depending on the product being refined. Comprehending these kinds will certainly help you pick the Tunnel pasteurizer that aligns best with your organization needs.

## Budgeting and Cost Evaluation

Thinking about the monetary aspects of buying a passage pasteurizer is an essential step in your service decision-making procedure. When https://www.theceomagazine.com/executive-interviews/food-beverage/bennett-neo/ for a passage pasteurizer, think about not just the first purchase price but likewise continuous expenses such as upkeep, energy consumption, and possible upgrades.

Conduct a comprehensive cost evaluation to figure out the overall expense of ownership over the lifespan of the devices. Look for Tunnel pasteurizers that offer an equilibrium between ahead of time costs and long-term financial savings via energy effectiveness and lowered maintenance demands.

Bear in mind to consider any extra expenses such as installation, training, and prospective downtime during application. Compare quotes from various distributors and consider negotiating for a far better bargain or exploring funding options to alleviate the monetary problem.

## Verdict

In conclusion, selecting the appropriate Tunnel pasteurizer for your business calls for careful factor to consider of variables such as dimension, capability, heating and cooling down abilities, maintenance needs, and technological support schedule. Evaluate various kinds of pasteurizers to locate the most effective suitable for your manufacturing demands and budget restrictions. Conduct https://www.deccanherald.com/business/paper-boat-juicing-recipe-right-2072557 detailed price evaluation to identify the complete possession price, including installation and potential downtime costs. With these factors in mind, you can make an informed decision that will certainly benefit your service in the future.

SPOILER ALERT!

The Future Of Food Handling: Developments In Batch Pasteurizers You Need To Know About

Authored By-Glass Pierce

As you consider the future of food handling, have you ever before questioned the latest improvements in batch pasteurizers that could reinvent the market? Visualize a globe where efficiency, food security, and sustainability are perfectly integrated right into the procedure, supplying a peek of what's ahead. Stay tuned to uncover how these advancements are improving the method food is processed and exactly how they may impact your procedures in the near future.

## Improved Effectiveness Through Automation

Aiming to enhance your pasteurization process? batch pasteurizers currently use enhanced efficiency via automation. By integrating advanced innovation, these contemporary systems can considerably enhance the speed and precision of your pasteurization procedures.

With automated controls and sensors, you can exactly keep an eye on and change variables such as temperature level and stress, guaranteeing optimum pasteurization conditions for your items.

Automation also minimizes the demand for hand-operated intervention, saving you time and labor expenses. These sophisticated batch pasteurizers can instantly regulate the circulation of items, identify irregularities, and even alert operators in case of any kind of problems. This not just enhances the total performance of your pasteurization process however likewise improves the uniformity and high quality of your end products.

Additionally, https://www.newswire.ca/news-releases/big-rock-brewery-announces-commissioning-of-new-can-line-in-calgary-830173670.html in reducing the risk of human errors, bring about more reliable and safe food processing. With these developments in batch pasteurizers, you can improve your operations, improve performance, and keep premium requirements in your food processing center.

## Boosted Food Safety Standards

To make sure the highest degree of food safety in your procedures, it's critical to execute enhanced requirements that line up with regulative requirements and sector finest methods. Enhancing food safety and security requirements entails strenuous tracking of vital control factors, detailed hygiene procedures, and detailed staff training. Routine audits and inspections aid in recognizing potential threats and making certain conformity with strict guidelines.

Buying sophisticated technologies such as automatic monitoring systems and information analytics can better reinforce your food safety measures. These developments supply real-time understandings into the production procedure, making it possible for punctual corrective actions when inconsistencies take place.

Carrying Out Hazard Analysis and Crucial Control Points (HACCP) concepts is vital for systematically attending to food safety and security dangers and protecting against contamination.

## Lasting Practices in Pasteurization

Including sustainable practices in pasteurization is crucial for minimizing ecological impact and improving operational performance. By applying energy-efficient modern technologies, such as heat recovery systems and automated controls, you can reduce source intake during the pasteurization process. Making use of water-saving techniques, like counter-current rinsing systems and reusing rinse water, helps in preserving this valuable source.

In addition, enhancing cleaning processes to decrease chemical use and wastewater generation more boosts sustainability in pasteurization procedures.

Choosing green packaging materials and implementing reusing programs for product packaging waste can dramatically reduce the total ecological footprint of your pasteurization procedures. Teaming up with vendors that prioritize lasting sourcing methods ensures that the components used in your products are created responsibly.

Furthermore, purchasing renewable resource sources, such as solar or wind power, for your pasteurization facilities can help lower greenhouse gas discharges and move in the direction of an extra sustainable future in food processing. By accepting lasting techniques in pasteurization, you not only contribute to ecological conservation yet likewise improve the overall efficiency and strength of your food handling procedures.

## Final thought

In conclusion, accepting innovations in batch pasteurizers can change the food processing industry by boosting performance, making sure food safety and security, and advertising sustainability. By incorporating automation functions, boosting food safety standards, and embracing lasting methods, firms can stay ahead of the contour and meet the developing needs of consumers and governing bodies. Stay positive in executing these innovations to remain competitive and drive positive change in the food handling industry.

As you consider the future of food handling, have you ever before questioned the latest improvements in batch pasteurizers that could reinvent the market? Visualize a globe where efficiency, food security, and sustainability are perfectly integrated right into the procedure, supplying a peek of what's ahead. Stay tuned to uncover how these advancements are improving the method food is processed and exactly how they may impact your procedures in the near future.

## Improved Effectiveness Through Automation

Aiming to enhance your pasteurization process? batch pasteurizers currently use enhanced efficiency via automation. By integrating advanced innovation, these contemporary systems can considerably enhance the speed and precision of your pasteurization procedures.

With automated controls and sensors, you can exactly keep an eye on and change variables such as temperature level and stress, guaranteeing optimum pasteurization conditions for your items.

Automation also minimizes the demand for hand-operated intervention, saving you time and labor expenses. These sophisticated batch pasteurizers can instantly regulate the circulation of items, identify irregularities, and even alert operators in case of any kind of problems. This not just enhances the total performance of your pasteurization process however likewise improves the uniformity and high quality of your end products.

Additionally, https://www.newswire.ca/news-releases/big-rock-brewery-announces-commissioning-of-new-can-line-in-calgary-830173670.html in reducing the risk of human errors, bring about more reliable and safe food processing. With these developments in batch pasteurizers, you can improve your operations, improve performance, and keep premium requirements in your food processing center.

## Boosted Food Safety Standards

To make sure the highest degree of food safety in your procedures, it's critical to execute enhanced requirements that line up with regulative requirements and sector finest methods. Enhancing food safety and security requirements entails strenuous tracking of vital control factors, detailed hygiene procedures, and detailed staff training. Routine audits and inspections aid in recognizing potential threats and making certain conformity with strict guidelines.

Buying sophisticated technologies such as automatic monitoring systems and information analytics can better reinforce your food safety measures. These developments supply real-time understandings into the production procedure, making it possible for punctual corrective actions when inconsistencies take place.

Carrying Out Hazard Analysis and Crucial Control Points (HACCP) concepts is vital for systematically attending to food safety and security dangers and protecting against contamination.

## Lasting Practices in Pasteurization

Including sustainable practices in pasteurization is crucial for minimizing ecological impact and improving operational performance. By applying energy-efficient modern technologies, such as heat recovery systems and automated controls, you can reduce source intake during the pasteurization process. Making use of water-saving techniques, like counter-current rinsing systems and reusing rinse water, helps in preserving this valuable source.

In addition, enhancing cleaning processes to decrease chemical use and wastewater generation more boosts sustainability in pasteurization procedures.

Choosing green packaging materials and implementing reusing programs for product packaging waste can dramatically reduce the total ecological footprint of your pasteurization procedures. Teaming up with vendors that prioritize lasting sourcing methods ensures that the components used in your products are created responsibly.

Furthermore, purchasing renewable resource sources, such as solar or wind power, for your pasteurization facilities can help lower greenhouse gas discharges and move in the direction of an extra sustainable future in food processing. By accepting lasting techniques in pasteurization, you not only contribute to ecological conservation yet likewise improve the overall efficiency and strength of your food handling procedures.

## Final thought

In conclusion, accepting innovations in batch pasteurizers can change the food processing industry by boosting performance, making sure food safety and security, and advertising sustainability. By incorporating automation functions, boosting food safety standards, and embracing lasting methods, firms can stay ahead of the contour and meet the developing needs of consumers and governing bodies. Stay positive in executing these innovations to remain competitive and drive positive change in the food handling industry.

SPOILER ALERT!

Recognizing The Benefits Of Batch Pasteurization: A Thorough Source For Food Manufacturers

Post By-Basse Franck

When it involves guaranteeing the security and top quality of foodstuff, batch pasteurizers use market experts an essential tool. By meticulously regulating time and temperature level specifications, these devices successfully remove harmful microorganisms and impurities, guarding the stability of food things. The role of batch pasteurizers surpasses plain sanitation; it includes an extensive technique to protecting nutritional worth and prolonging shelf life. As you think about the diverse effect of batch pasteurizers on food safety and top quality, you'll discover vital insights that can raise your sector practices.

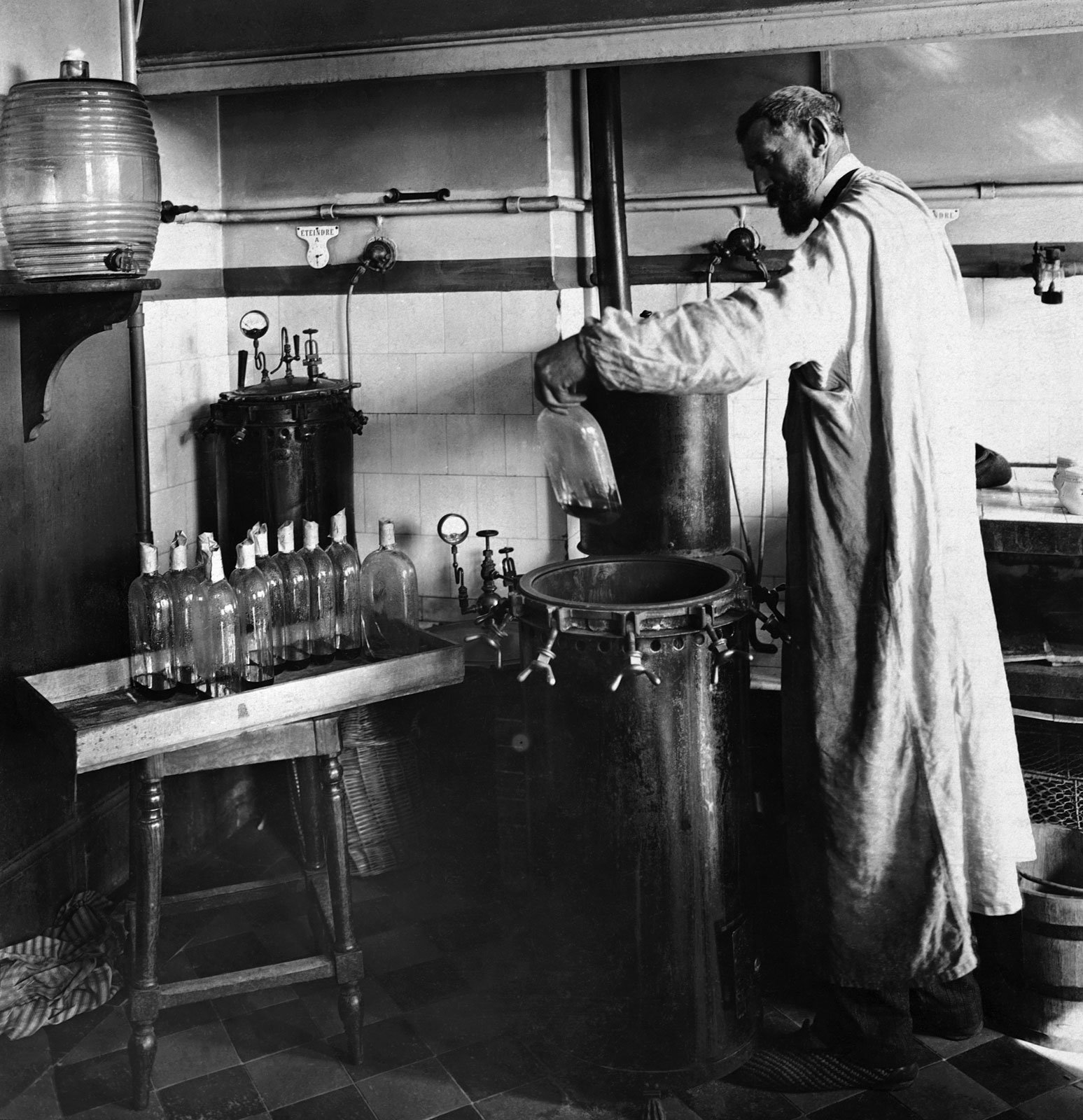

## Value of batch Pasteurizers

When it pertains to guaranteeing food safety and security and high quality, batch pasteurizers play a crucial duty. These makers are necessary for getting rid of harmful germs and virus from food products, avoiding foodborne health problems, and expanding the service life of disposable items. By subjecting food to regulated temperature levels, batch pasteurizers properly damage damaging bacteria that might or else pollute the food supply chain. This process not just safeguards consumer health yet likewise preserves the integrity and quality of the food being processed.

Along with enhancing food safety and security, batch pasteurizers are instrumental in preserving the dietary worth of foodstuff. official website employed by these devices assists preserve vitamins, minerals, and other necessary nutrients in the food, making sure that consumers obtain items that aren't just secure yet likewise healthy.

Moreover, batch pasteurizers contribute to maintaining the taste, structure, and total high quality of food things, supplying consumers with products that satisfy high requirements of taste and freshness.

## Conveniences for Food Safety And Security

To guarantee ideal food security criteria, batch pasteurizers offer a series of advantages that are important in the food processing industry. These pasteurizers successfully eliminate dangerous bacteria, pathogens, and various other pollutants that can endanger the safety of foodstuff. By subjecting the food to exact time and temperature level controls during the pasteurization procedure, batch pasteurizers aid damage microbes that may cause foodborne illnesses. This causes a substantial reduction in the threat of virus entering the food supply chain, consequently improving customer security.

batch pasteurizers also contribute to extending the service life of different food. By removing dangerous bacteria, molds, and yeasts, these pasteurizers hinder spoilage and preserve the quality of foods for longer periods. This not just enhances food safety and security but likewise minimizes food waste, ensuring that items continue to be secure for intake over a prolonged period.

Furthermore, batch pasteurizers supply a reputable and consistent technique for accomplishing food safety and security requirements, enabling food handling facilities to satisfy regulative needs and provide premium, secure products to consumers. By buying batch pasteurization innovation, food industry specialists can enhance food security methods and construct trust fund with their customers.

## Enhancing Product High Quality

With batch pasteurizers, you can not just make certain food safety and security but likewise boost the total top quality of your products. By utilizing batch pasteurization techniques, you can achieve better conservation of tastes, textures, and nutrients in your food products. https://www.craftbrewingbusiness.com/featured/distribution-update-blakes-beverage-goes-to-japan-moves-from-holidaily-brewing-real-american-beer-and-more/ supplied by batch pasteurizers assists keep the integrity of your components, leading to a better final result that maintains its quality and taste for longer periods.

Furthermore, batch pasteurization assists in lowering the microbial load in your items without compromising their sensory features. This means that you can provide more secure products to customers while ensuring that they fulfill the highest quality requirements.

The specific control over temperature and time parameters supplied by batch pasteurizers makes sure that your products are sterilized successfully, causing enhanced high quality and expanded life span.

## Verdict

To conclude, batch pasteurizers are crucial for market specialists aiming to improve food safety and top quality. By efficiently removing dangerous bacteria and microorganisms, these devices make certain the manufacturing of top quality, risk-free foodstuff for customers. With exact time and temperature controls throughout pasteurization, batch pasteurizers play an essential role in maintaining the nutritional worth of food and prolonging life span. Incorporating batch pasteurizers into food production procedures is essential to making sure consumer wellness and well-being.

When it involves guaranteeing the security and top quality of foodstuff, batch pasteurizers use market experts an essential tool. By meticulously regulating time and temperature level specifications, these devices successfully remove harmful microorganisms and impurities, guarding the stability of food things. The role of batch pasteurizers surpasses plain sanitation; it includes an extensive technique to protecting nutritional worth and prolonging shelf life. As you think about the diverse effect of batch pasteurizers on food safety and top quality, you'll discover vital insights that can raise your sector practices.

## Value of batch Pasteurizers

When it pertains to guaranteeing food safety and security and high quality, batch pasteurizers play a crucial duty. These makers are necessary for getting rid of harmful germs and virus from food products, avoiding foodborne health problems, and expanding the service life of disposable items. By subjecting food to regulated temperature levels, batch pasteurizers properly damage damaging bacteria that might or else pollute the food supply chain. This process not just safeguards consumer health yet likewise preserves the integrity and quality of the food being processed.

Along with enhancing food safety and security, batch pasteurizers are instrumental in preserving the dietary worth of foodstuff. official website employed by these devices assists preserve vitamins, minerals, and other necessary nutrients in the food, making sure that consumers obtain items that aren't just secure yet likewise healthy.

Moreover, batch pasteurizers contribute to maintaining the taste, structure, and total high quality of food things, supplying consumers with products that satisfy high requirements of taste and freshness.

## Conveniences for Food Safety And Security

To guarantee ideal food security criteria, batch pasteurizers offer a series of advantages that are important in the food processing industry. These pasteurizers successfully eliminate dangerous bacteria, pathogens, and various other pollutants that can endanger the safety of foodstuff. By subjecting the food to exact time and temperature level controls during the pasteurization procedure, batch pasteurizers aid damage microbes that may cause foodborne illnesses. This causes a substantial reduction in the threat of virus entering the food supply chain, consequently improving customer security.

batch pasteurizers also contribute to extending the service life of different food. By removing dangerous bacteria, molds, and yeasts, these pasteurizers hinder spoilage and preserve the quality of foods for longer periods. This not just enhances food safety and security but likewise minimizes food waste, ensuring that items continue to be secure for intake over a prolonged period.

Furthermore, batch pasteurizers supply a reputable and consistent technique for accomplishing food safety and security requirements, enabling food handling facilities to satisfy regulative needs and provide premium, secure products to consumers. By buying batch pasteurization innovation, food industry specialists can enhance food security methods and construct trust fund with their customers.

## Enhancing Product High Quality

With batch pasteurizers, you can not just make certain food safety and security but likewise boost the total top quality of your products. By utilizing batch pasteurization techniques, you can achieve better conservation of tastes, textures, and nutrients in your food products. https://www.craftbrewingbusiness.com/featured/distribution-update-blakes-beverage-goes-to-japan-moves-from-holidaily-brewing-real-american-beer-and-more/ supplied by batch pasteurizers assists keep the integrity of your components, leading to a better final result that maintains its quality and taste for longer periods.

Furthermore, batch pasteurization assists in lowering the microbial load in your items without compromising their sensory features. This means that you can provide more secure products to customers while ensuring that they fulfill the highest quality requirements.

The specific control over temperature and time parameters supplied by batch pasteurizers makes sure that your products are sterilized successfully, causing enhanced high quality and expanded life span.

## Verdict

To conclude, batch pasteurizers are crucial for market specialists aiming to improve food safety and top quality. By efficiently removing dangerous bacteria and microorganisms, these devices make certain the manufacturing of top quality, risk-free foodstuff for customers. With exact time and temperature controls throughout pasteurization, batch pasteurizers play an essential role in maintaining the nutritional worth of food and prolonging life span. Incorporating batch pasteurizers into food production procedures is essential to making sure consumer wellness and well-being.

SPOILER ALERT!

Everything You Required To Know About Tunnel Pasteurizers: Functionality And Relevance

Post Written By-MacMillan Begum

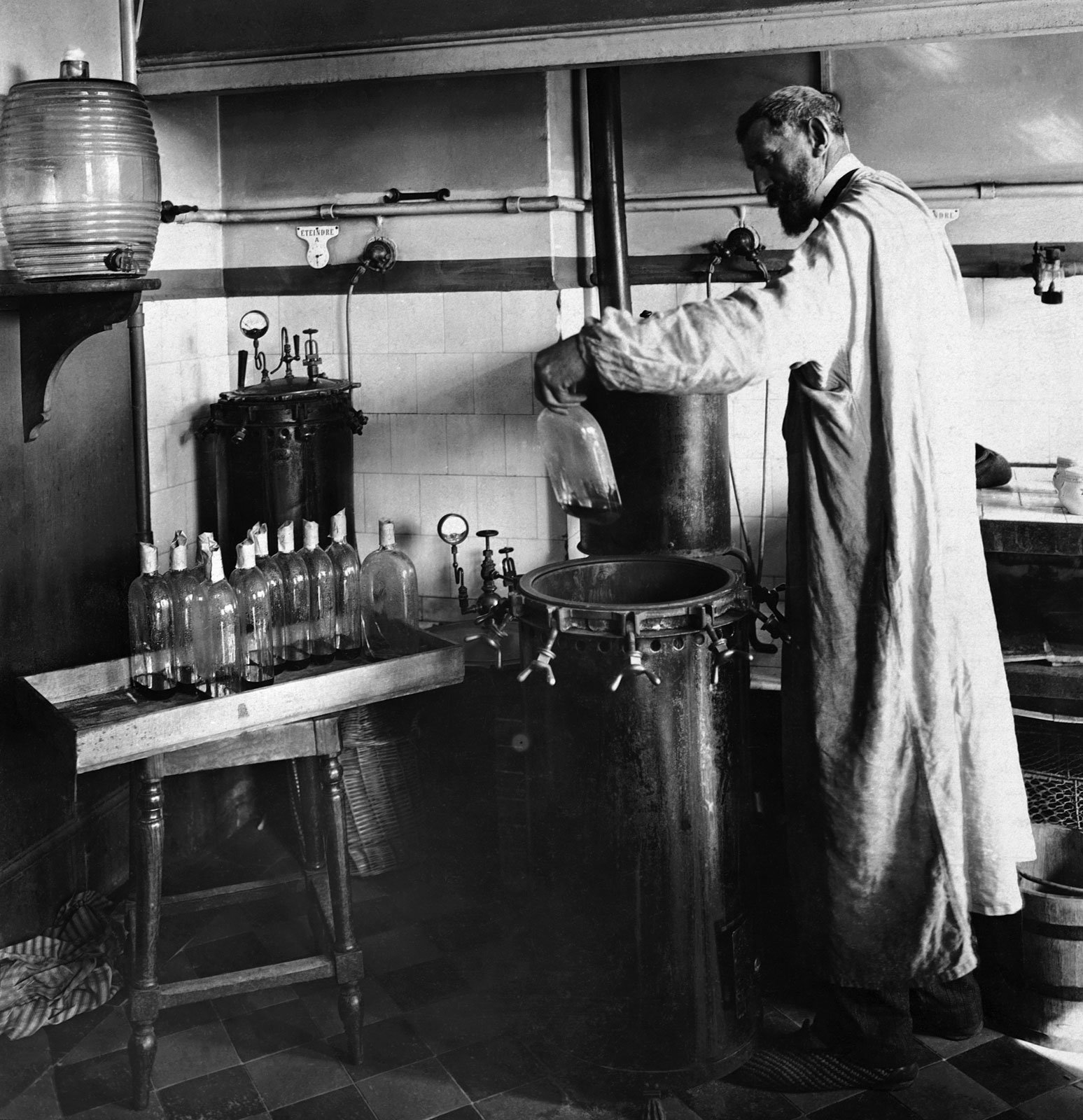

Tunnel pasteurizers help lengthen beer shelf security and keep tastes standing out without the help of chemicals. They do this while killing pathogens and inactivating yeast and mold and mildews.

The bottled product, either bottles or containers, enters the Tunnel and experiences a pre-heating section where it gets splashed with hot water. From there, it's slowly given the preferred pasteurization temperature and afterwards cooled down.

Tunnel pasteurizers utilize a conveyor system to move products via a temperature-controlled Tunnel. As the beer cans and containers relocate with the Tunnel, they are continually splashed with warm water, which progressively elevates their temperatures till they reach the preferred pasteurization level. After that, the containers are held at that temperature for a collection amount of time and afterwards cooled again.

After the pasteurization procedure is complete, the beer cans and bottles are moved to a cooling Tunnel where their temperature levels are reduced incrementally until they reach space temperature once more. This is done to avoid the drinks from experiencing an unexpected cool shock, which could modify their flavor profiles.

While Tunnel pasteurizers can be made use of by both big and tiny breweries, it is very important that the best one is selected for your brewery. It's finest to select a system developed and built by relied on, experienced market professionals. This will certainly guarantee that your system can deal with the details temperature level levels and timing needed for carbonated beverages while also pairing up with your assembly line's flow.

Tunnel pasteurizers provide a reliable service to extending service life without endangering item quality. While flash pasteurizers can only target the fluid inside the plan, Tunnel machines heat both the container and the components - implying they can prolong a beer's shelf stability without impacting its intricate hop notes.

In addition, passages are wonderful for soft drinks also - no need to worry about the heat destroying those fizzy bubbles. Particularly for craft breweries, Tunnel pasteurization is an indispensable device to ensure their products' durable shelf stability-- all without threatening the delicious preference that consumers enjoy.

Besides being effective, Tunnel pasteurizers are also adaptable and adjustable. Temperature levels in the various zones can be maximized to minimize power consumption and keep optimum pasteurization levels. This is attained by adjusting the heating & cooling temperatures to match the demands of the specific drink being treated (2 ). Furthermore, the splashing nozzles can additionally be personalized to fit the bottle size and setup.

Simply put, Tunnel pasteurizers are a helpful tool for breweries and other drink manufacturers aiming to expand their beverages' life span. They can be used to kill off any virus or microbes in the fluid and its product packaging. This will help to avoid the beverages from spoiling or weakening prior to they get to customers.

A tunnel pasteurizer is a maker that takes the already-bottled item and passes it via numerous temperature level zones with boosting heat, up until it gets to the preferred pasteurization temperature. Then it is cooled off.

The heating and cooling of the containers in a passage pasteurizer is executed utilizing a series of spray nozzles. The exact positioning of these nozzles makes best use of the result and reduces the mixing of water between different zones. They are likewise optimized to decrease energy consumption. Furthermore, they're risk-free for carbonated beverages - so they can shield your carbonated beers from over-carbonation and guarantee their longevity. This is specifically vital for craft breweries and other drink manufacturers that want to keep their customers pleased.

Tunnel pasteurizers are a large piece of equipment that contains an enclosed conveyor belt system where the bottles or canisters move through areas that each have a certain temperature and dwell time. When the products are sprayed or submersed in hot water and held at that temperature for the appropriate quantity of time, they're after that rapidly cooled off and allowed to make their way out of the equipment.

Tunnel pasteurization is a great method to extend the shelf life of your beer and assistance avoid dangerous pollutants from ruining your beverage. Nevertheless, due to the fact that it warms up the liquid so long, a number of the attributes that offer your beers their scrumptious taste and fragrance can also get ruined at the same time.

One choice to Tunnel pasteurization is flash pasteurization, which heats the beer for a much shorter time period and aids preserve those specialized components you functioned so hard to resource for your beers. While click the up coming article does cost more ahead of time, it can conserve you cash over time by avoiding expensive food and drink recalls.

Tunnel pasteurizers help lengthen beer shelf security and keep tastes standing out without the help of chemicals. They do this while killing pathogens and inactivating yeast and mold and mildews.

The bottled product, either bottles or containers, enters the Tunnel and experiences a pre-heating section where it gets splashed with hot water. From there, it's slowly given the preferred pasteurization temperature and afterwards cooled down.

Just how They Work

Tunnel pasteurizers utilize a conveyor system to move products via a temperature-controlled Tunnel. As the beer cans and containers relocate with the Tunnel, they are continually splashed with warm water, which progressively elevates their temperatures till they reach the preferred pasteurization level. After that, the containers are held at that temperature for a collection amount of time and afterwards cooled again.

After the pasteurization procedure is complete, the beer cans and bottles are moved to a cooling Tunnel where their temperature levels are reduced incrementally until they reach space temperature once more. This is done to avoid the drinks from experiencing an unexpected cool shock, which could modify their flavor profiles.

While Tunnel pasteurizers can be made use of by both big and tiny breweries, it is very important that the best one is selected for your brewery. It's finest to select a system developed and built by relied on, experienced market professionals. This will certainly guarantee that your system can deal with the details temperature level levels and timing needed for carbonated beverages while also pairing up with your assembly line's flow.

Why They're Essential

Tunnel pasteurizers provide a reliable service to extending service life without endangering item quality. While flash pasteurizers can only target the fluid inside the plan, Tunnel machines heat both the container and the components - implying they can prolong a beer's shelf stability without impacting its intricate hop notes.

In addition, passages are wonderful for soft drinks also - no need to worry about the heat destroying those fizzy bubbles. Particularly for craft breweries, Tunnel pasteurization is an indispensable device to ensure their products' durable shelf stability-- all without threatening the delicious preference that consumers enjoy.

Besides being effective, Tunnel pasteurizers are also adaptable and adjustable. Temperature levels in the various zones can be maximized to minimize power consumption and keep optimum pasteurization levels. This is attained by adjusting the heating & cooling temperatures to match the demands of the specific drink being treated (2 ). Furthermore, the splashing nozzles can additionally be personalized to fit the bottle size and setup.

What You Required to Know

Simply put, Tunnel pasteurizers are a helpful tool for breweries and other drink manufacturers aiming to expand their beverages' life span. They can be used to kill off any virus or microbes in the fluid and its product packaging. This will help to avoid the beverages from spoiling or weakening prior to they get to customers.

A tunnel pasteurizer is a maker that takes the already-bottled item and passes it via numerous temperature level zones with boosting heat, up until it gets to the preferred pasteurization temperature. Then it is cooled off.

The heating and cooling of the containers in a passage pasteurizer is executed utilizing a series of spray nozzles. The exact positioning of these nozzles makes best use of the result and reduces the mixing of water between different zones. They are likewise optimized to decrease energy consumption. Furthermore, they're risk-free for carbonated beverages - so they can shield your carbonated beers from over-carbonation and guarantee their longevity. This is specifically vital for craft breweries and other drink manufacturers that want to keep their customers pleased.

The Final Words

Tunnel pasteurizers are a large piece of equipment that contains an enclosed conveyor belt system where the bottles or canisters move through areas that each have a certain temperature and dwell time. When the products are sprayed or submersed in hot water and held at that temperature for the appropriate quantity of time, they're after that rapidly cooled off and allowed to make their way out of the equipment.

Tunnel pasteurization is a great method to extend the shelf life of your beer and assistance avoid dangerous pollutants from ruining your beverage. Nevertheless, due to the fact that it warms up the liquid so long, a number of the attributes that offer your beers their scrumptious taste and fragrance can also get ruined at the same time.

One choice to Tunnel pasteurization is flash pasteurization, which heats the beer for a much shorter time period and aids preserve those specialized components you functioned so hard to resource for your beers. While click the up coming article does cost more ahead of time, it can conserve you cash over time by avoiding expensive food and drink recalls.

SPOILER ALERT!

The Ultimate Overview To Tunnel Pasteurizers: Just How They Function And Why They're Important

Composed By-Davidson Begum

Tunnel pasteurizers assist prolong beer rack security and keep tastes standing out without the help of chemicals. They do this while killing microorganisms and suspending yeast and molds.

The bottled item, either bottles or containers, goes into the Tunnel and experiences a pre-heating area where it obtains splashed with hot water. From there, it's slowly brought to the wanted pasteurization temperature and afterwards cooled.

Tunnel pasteurizers use a conveyor system to relocate products with a temperature-controlled Tunnel. As the beer cans and bottles relocate via the Tunnel, they are constantly splashed with warm water, which slowly increases their temperature levels until they reach the wanted pasteurization degree. After that, the containers are held at that temperature level for a collection amount of time and after that cooled off once again.

After just click the up coming document is full, the beer containers and containers are relocated to an air conditioning Tunnel where their temperature levels are reduced incrementally up until they reach room temperature again. This is done to avoid the drinks from experiencing an unexpected chilly shock, which can modify their flavor profiles.

While Tunnel pasteurizers can be used by both huge and little breweries, it's important that the ideal one is picked for your brewery. It's best to choose a system developed and constructed by trusted, experienced sector specialists. This will certainly guarantee that your system can take care of the specific temperature level levels and timing needed for carbonated beverages while also comparing with your assembly line's circulation.

Tunnel pasteurizers deliver an effective remedy to extending shelf life without endangering product high quality. While flash pasteurizers can just target the liquid inside the package, Tunnel devices warmth both the container and the components - implying they can extend a beer's rack security without impacting its intricate hop notes.

Additionally, passages are excellent for soft drinks as well - no need to fret about the high temperature destroying those fizzy bubbles. Especially for craft breweries, Tunnel pasteurization is an important device to ensure their items' resilient shelf stability-- all without jeopardizing the tasty preference that consumers enjoy.

Besides being effective, Tunnel pasteurizers are also adaptable and adjustable. Temperature levels in the various areas can be optimized to lower energy consumption and preserve optimal pasteurization levels. This is achieved by adjusting the heating and cooling temperatures to match the needs of the particular beverage being dealt with (2 ). Furthermore, the splashing nozzles can also be customized to fit the bottle size and configuration.

In short, Tunnel pasteurizers are an useful device for breweries and various other drink manufacturers seeking to prolong their drinks' service life. They can be utilized to exterminate any kind of virus or microbes in the liquid and its packaging. This will certainly help to stop the beverages from ruining or wearing away before they get to customers.

A tunnel pasteurizer is an equipment that takes the already-bottled item and passes it through numerous temperature level zones with increasing warmth, up until it gets to the desired pasteurization temperature level. Then it is cooled down.

The heating and cooling of the containers in a passage pasteurizer is accomplished utilizing a series of spray nozzles. The specific positioning of these nozzles makes best use of the effect and lessens the mixing of water in between different areas. They are additionally maximized to decrease power consumption. Additionally, they're safe for carbonated beverages - so they can protect your carbonated beers from over-carbonation and ensure their durability. This is especially essential for craft breweries and other beverage producers that wish to maintain their customers satisfied.

Tunnel pasteurizers are a large piece of machinery which contains an enclosed conveyor belt system where the bottles or containers move via areas that each have a certain temperature and dwell time. Once the products are splashed or immersed in hot water and held at that temperature for the suitable amount of time, they're after that swiftly cooled and permitted to make their escape of the device.

Tunnel pasteurization is a wonderful method to expand the service life of your beer and aid stop damaging pollutants from spoiling your drink. Nevertheless, since it heats up the liquid as long, much of the qualities that provide your beers their tasty taste and aroma can additionally get destroyed while doing so.

One alternative to Tunnel pasteurization is flash pasteurization, which heats up the beer for a shorter time period and helps protect those specialized ingredients you functioned so hard to source for your beers. While flash pasteurization does cost more upfront, it can save you cash in the future by preventing costly food and drink recalls.

Tunnel pasteurizers assist prolong beer rack security and keep tastes standing out without the help of chemicals. They do this while killing microorganisms and suspending yeast and molds.

The bottled item, either bottles or containers, goes into the Tunnel and experiences a pre-heating area where it obtains splashed with hot water. From there, it's slowly brought to the wanted pasteurization temperature and afterwards cooled.

Exactly how They Work

Tunnel pasteurizers use a conveyor system to relocate products with a temperature-controlled Tunnel. As the beer cans and bottles relocate via the Tunnel, they are constantly splashed with warm water, which slowly increases their temperature levels until they reach the wanted pasteurization degree. After that, the containers are held at that temperature level for a collection amount of time and after that cooled off once again.

After just click the up coming document is full, the beer containers and containers are relocated to an air conditioning Tunnel where their temperature levels are reduced incrementally up until they reach room temperature again. This is done to avoid the drinks from experiencing an unexpected chilly shock, which can modify their flavor profiles.

While Tunnel pasteurizers can be used by both huge and little breweries, it's important that the ideal one is picked for your brewery. It's best to choose a system developed and constructed by trusted, experienced sector specialists. This will certainly guarantee that your system can take care of the specific temperature level levels and timing needed for carbonated beverages while also comparing with your assembly line's circulation.

Why They're Important

Tunnel pasteurizers deliver an effective remedy to extending shelf life without endangering product high quality. While flash pasteurizers can just target the liquid inside the package, Tunnel devices warmth both the container and the components - implying they can extend a beer's rack security without impacting its intricate hop notes.

Additionally, passages are excellent for soft drinks as well - no need to fret about the high temperature destroying those fizzy bubbles. Especially for craft breweries, Tunnel pasteurization is an important device to ensure their items' resilient shelf stability-- all without jeopardizing the tasty preference that consumers enjoy.

Besides being effective, Tunnel pasteurizers are also adaptable and adjustable. Temperature levels in the various areas can be optimized to lower energy consumption and preserve optimal pasteurization levels. This is achieved by adjusting the heating and cooling temperatures to match the needs of the particular beverage being dealt with (2 ). Furthermore, the splashing nozzles can also be customized to fit the bottle size and configuration.

What You Need to Know

In short, Tunnel pasteurizers are an useful device for breweries and various other drink manufacturers seeking to prolong their drinks' service life. They can be utilized to exterminate any kind of virus or microbes in the liquid and its packaging. This will certainly help to stop the beverages from ruining or wearing away before they get to customers.

A tunnel pasteurizer is an equipment that takes the already-bottled item and passes it through numerous temperature level zones with increasing warmth, up until it gets to the desired pasteurization temperature level. Then it is cooled down.

The heating and cooling of the containers in a passage pasteurizer is accomplished utilizing a series of spray nozzles. The specific positioning of these nozzles makes best use of the effect and lessens the mixing of water in between different areas. They are additionally maximized to decrease power consumption. Additionally, they're safe for carbonated beverages - so they can protect your carbonated beers from over-carbonation and ensure their durability. This is especially essential for craft breweries and other beverage producers that wish to maintain their customers satisfied.

The Final Words

Tunnel pasteurizers are a large piece of machinery which contains an enclosed conveyor belt system where the bottles or containers move via areas that each have a certain temperature and dwell time. Once the products are splashed or immersed in hot water and held at that temperature for the suitable amount of time, they're after that swiftly cooled and permitted to make their escape of the device.

Tunnel pasteurization is a wonderful method to expand the service life of your beer and aid stop damaging pollutants from spoiling your drink. Nevertheless, since it heats up the liquid as long, much of the qualities that provide your beers their tasty taste and aroma can additionally get destroyed while doing so.

One alternative to Tunnel pasteurization is flash pasteurization, which heats up the beer for a shorter time period and helps protect those specialized ingredients you functioned so hard to source for your beers. While flash pasteurization does cost more upfront, it can save you cash in the future by preventing costly food and drink recalls.

SPOILER ALERT!

Whatever You Need To Know About Tunnel Pasteurizers: Capability And Importance

simply click the next internet page Develop By-MacMillan Begum

Tunnel pasteurizers aid prolong beer rack stability and keep flavors standing out without the aid of chemicals. They do this while killing pathogens and suspending yeast and mold and mildews.

The bottled product, either bottles or cans, gets in the Tunnel and undergoes a pre-heating area where it obtains splashed with warm water. From there, it's gradually offered the wanted pasteurization temperature and after that cooled down.

Tunnel pasteurizers utilize a conveyor system to relocate items via a temperature-controlled Tunnel. As the beer cans and bottles move through the Tunnel, they are continually sprayed with hot water, which gradually increases their temperatures until they get to the desired pasteurization degree. Then, the containers are held at that temperature for a collection amount of time and then cooled down again.

After the pasteurization procedure is total, the beer canisters and containers are moved to a cooling Tunnel where their temperatures are decreased incrementally up until they reach space temperature level once again. This is done to avoid the beverages from experiencing an abrupt cool shock, which can modify their taste profiles.

While Tunnel pasteurizers can be made use of by both large and tiny breweries, it's important that the best one is chosen for your brewery. It's best to select a system designed and built by trusted, experienced market professionals. This will certainly make sure that your system can manage the certain temperature levels and timing required for carbonated beverages while also pairing up with your production line's flow.

Tunnel pasteurizers provide an efficient option to prolonging shelf life without jeopardizing item quality. While flash pasteurizers can only target the liquid inside the package, Tunnel devices warmth both the container and the components - implying they can extend a beer's rack security without affecting its intricate hop notes.

In addition, passages are wonderful for carbonated drinks too - no need to stress over the heat ruining those carbonated bubbles. Especially for craft breweries, Tunnel pasteurization is a vital tool to guarantee their items' durable shelf security-- all without endangering the scrumptious taste that customers like.

Besides being efficient, Tunnel pasteurizers are additionally versatile and personalized. Temperature levels in the various zones can be maximized to decrease power consumption and preserve optimum pasteurization levels. This is achieved by adjusting the heating & cooling temperatures to match the demands of the particular beverage being dealt with (2 ). Moreover, the splashing nozzles can likewise be customized to fit the bottle size and setup.

Simply put, Tunnel pasteurizers are a helpful device for breweries and various other drink manufacturers seeking to expand their drinks' life span. They can be used to kill off any pathogens or microbes in the fluid and its packaging. This will aid to prevent the drinks from ruining or wearing away before they get to consumers.

A passage pasteurizer is an equipment that takes the already-bottled product and passes it via numerous temperature zones with boosting warm, till it reaches the desired pasteurization temperature level. Then it is cooled off.

The heating & cooling of the containers in a passage pasteurizer is accomplished using a collection of spray nozzles. The accurate positioning of these nozzles optimizes the impact and decreases the mixing of water in between different areas. They are additionally enhanced to lower energy intake. Additionally, they're secure for carbonated beverages - so they can safeguard your fizzy beers from over-carbonation and ensure their long life. https://bangordailynews.com/2017/01/05/living/for-quality-small-batch-butter-try-churning-it-at-home/ is particularly essential for craft breweries and other beverage manufacturers that wish to keep their customers satisfied.

Tunnel pasteurizers are a large piece of equipment which contains an encased conveyor belt system where the bottles or canisters relocate with zones that each have a details temperature level and dwell time. As soon as the items are splashed or submersed in hot water and held at that temperature level for the suitable amount of time, they're after that rapidly cooled and allowed to make their escape of the machine.

Tunnel pasteurization is a great way to extend the life span of your beer and aid protect against harmful contaminants from ruining your drink. Nonetheless, since it heats up the liquid so long, many of the attributes that give your beers their delicious flavor and scent can also get damaged while doing so.

One alternative to Tunnel pasteurization is flash pasteurization, which heats the beer for a shorter amount of time and aids maintain those specialized active ingredients you worked so difficult to source for your beers. While flash pasteurization does cost more upfront, it can conserve you money in the long run by protecting against costly food and drink remembers.

Tunnel pasteurizers aid prolong beer rack stability and keep flavors standing out without the aid of chemicals. They do this while killing pathogens and suspending yeast and mold and mildews.

The bottled product, either bottles or cans, gets in the Tunnel and undergoes a pre-heating area where it obtains splashed with warm water. From there, it's gradually offered the wanted pasteurization temperature and after that cooled down.

How They Work

Tunnel pasteurizers utilize a conveyor system to relocate items via a temperature-controlled Tunnel. As the beer cans and bottles move through the Tunnel, they are continually sprayed with hot water, which gradually increases their temperatures until they get to the desired pasteurization degree. Then, the containers are held at that temperature for a collection amount of time and then cooled down again.

After the pasteurization procedure is total, the beer canisters and containers are moved to a cooling Tunnel where their temperatures are decreased incrementally up until they reach space temperature level once again. This is done to avoid the beverages from experiencing an abrupt cool shock, which can modify their taste profiles.

While Tunnel pasteurizers can be made use of by both large and tiny breweries, it's important that the best one is chosen for your brewery. It's best to select a system designed and built by trusted, experienced market professionals. This will certainly make sure that your system can manage the certain temperature levels and timing required for carbonated beverages while also pairing up with your production line's flow.

Why They're Essential

Tunnel pasteurizers provide an efficient option to prolonging shelf life without jeopardizing item quality. While flash pasteurizers can only target the liquid inside the package, Tunnel devices warmth both the container and the components - implying they can extend a beer's rack security without affecting its intricate hop notes.

In addition, passages are wonderful for carbonated drinks too - no need to stress over the heat ruining those carbonated bubbles. Especially for craft breweries, Tunnel pasteurization is a vital tool to guarantee their items' durable shelf security-- all without endangering the scrumptious taste that customers like.

Besides being efficient, Tunnel pasteurizers are additionally versatile and personalized. Temperature levels in the various zones can be maximized to decrease power consumption and preserve optimum pasteurization levels. This is achieved by adjusting the heating & cooling temperatures to match the demands of the particular beverage being dealt with (2 ). Moreover, the splashing nozzles can likewise be customized to fit the bottle size and setup.

What You Need to Know

Simply put, Tunnel pasteurizers are a helpful device for breweries and various other drink manufacturers seeking to expand their drinks' life span. They can be used to kill off any pathogens or microbes in the fluid and its packaging. This will aid to prevent the drinks from ruining or wearing away before they get to consumers.

A passage pasteurizer is an equipment that takes the already-bottled product and passes it via numerous temperature zones with boosting warm, till it reaches the desired pasteurization temperature level. Then it is cooled off.

The heating & cooling of the containers in a passage pasteurizer is accomplished using a collection of spray nozzles. The accurate positioning of these nozzles optimizes the impact and decreases the mixing of water in between different areas. They are additionally enhanced to lower energy intake. Additionally, they're secure for carbonated beverages - so they can safeguard your fizzy beers from over-carbonation and ensure their long life. https://bangordailynews.com/2017/01/05/living/for-quality-small-batch-butter-try-churning-it-at-home/ is particularly essential for craft breweries and other beverage manufacturers that wish to keep their customers satisfied.

The Final Words

Tunnel pasteurizers are a large piece of equipment which contains an encased conveyor belt system where the bottles or canisters relocate with zones that each have a details temperature level and dwell time. As soon as the items are splashed or submersed in hot water and held at that temperature level for the suitable amount of time, they're after that rapidly cooled and allowed to make their escape of the machine.

Tunnel pasteurization is a great way to extend the life span of your beer and aid protect against harmful contaminants from ruining your drink. Nonetheless, since it heats up the liquid so long, many of the attributes that give your beers their delicious flavor and scent can also get damaged while doing so.

One alternative to Tunnel pasteurization is flash pasteurization, which heats the beer for a shorter amount of time and aids maintain those specialized active ingredients you worked so difficult to source for your beers. While flash pasteurization does cost more upfront, it can conserve you money in the long run by protecting against costly food and drink remembers.

SPOILER ALERT!

Enhancing Efficiency: Streamlining Your Production Procedures With Tunnel Pasteurization Systems

Short Article By-Suhr Vick

Tunnel pasteurizers are big industrial-scale makers that warm and awesome beverages in order to kill microorganisms and prolong their life span. Their efficiency depends upon accuracy control.

A number of beverage firms have actually retrofitted their existing Tunnel pasteurizers with brand-new green modern technologies to attain substantial ecological advantages. These consist of reduced power consumption, lower water usage and decreased greenhouse gas discharges.

When you run a brewery, your objective isn't just to eliminate unsafe pathogens, but likewise to offer uniformity in your products. A well-executed pasteurization procedure not only prolongs beer's shelf life, however it makes certain that every container of your beer will certainly taste the very same, from your very first set to your last. This is particularly important for craft breweries wanting to bring in health-conscious customers who desire the carbonated goodness of soft drinks.

Tunnel pasteurizers work by bringing bottles and canisters up to their wanted temperature in phases, holding them there for long enough to exterminate the microbes that cause spoilage. They after that bring them down once again in step-by-step steps up until they reach space temperature, preserving taste profiles. By doing this, they not just stop bacteria from increasing in the item, but they likewise lower power usage by eliminating warm loss. These are the sort of efficiency gains that can accumulate promptly.

As even more focus is placed on eco-friendly manufacturing practices, beverage suppliers are searching for methods to minimize their waste production. Tunnel pasteurizers do a great task of this, particularly when they are developed and developed by seasoned specialists.

Tunnel pasteurizers make use of a series of sprays to heat the bottles or containers as they relocate via the device. This gets rid of the demand for a large steam container that consumes power and drainages. On top of that, Tunnel pasteurizers use a water savings system to recycle the hot water used in the home heating process, which minimizes water and sewer use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a large marketing point for craft brewers who want to prolong their items' service life and ensure uniformity between batches. Unlike flash pasteurizers, which often have problem with high degrees of carbonation, Tunnel systems can manage these effervescent mixtures without breaking a sweat (or a container).

When your drinks are effectively dealt with in Tunnel pasteurizers, they're safeguarded from unsafe microorganisms while protecting their taste accounts. This implies your brews, soft drinks, acid maintains (like fruits or acids), and wellness shots can extend their service life without shedding their trademark preference.

In order to accomplish this, tunnels include precise temperature level control and even distribution throughout their several phases. In addition, conveyor belt rates aid ensure equal treatment times for each and every bottle entering the machine. All this aids you ensure high quality results every time.

Finally, tunnels work with carbonated beverages, an expanding pattern amongst health-conscious consumers seeking carbonated choices to sweet sodas. Unlike flash pasteurizers, which can fight with high-carbonation levels, Tunnel equipments are designed to manage them.

Additionally, retrofitting tunnels with energy recovery systems reduces water usage also. By utilizing the retrieved water for air conditioning, you'll considerably cut your power consumption and greenhouse gas emissions.

Tunnel pasteurizers are energy-intensive machines, yet you can decrease your power intake by retrofitting them with advanced environment-friendly innovation. This includes solar-powered heating elements that can operate on renewable resource sources, reducing dependence on fossil fuels and your carbon impact.

An additional wonderful feature of Tunnel pasteurizers is that they are compatible with carbonated beverages, a popular trend among today's health-conscious customers. Unlike flash pasteurizers, which occasionally deal with high-carbonation levels, Tunnel devices can take care of these fizzy mixtures with ease.

zPasteurAIzer can keep track of the effectiveness of your present Tunnel pasteurizer by estimating the built up item high quality (PU) worth for each and every set. This enables you to establish if your present temperature level control system is delivering enough warm therapy along with recognizing any kind of curved spray heads. https://www.foodprocessing.com/articles/2017/gentler-processes-for-pasteurization-and-sterilization/ can then readjust the equipment setups based on your favored PU worths, enhancing manufacturing efficiency while decreasing power intake. This is an excellent method to cut down your water usage too, straightening your service with consumer demand for ecologically liable products.

Tunnel pasteurizers are big industrial-scale makers that warm and awesome beverages in order to kill microorganisms and prolong their life span. Their efficiency depends upon accuracy control.

A number of beverage firms have actually retrofitted their existing Tunnel pasteurizers with brand-new green modern technologies to attain substantial ecological advantages. These consist of reduced power consumption, lower water usage and decreased greenhouse gas discharges.

1. Increased Productivity

When you run a brewery, your objective isn't just to eliminate unsafe pathogens, but likewise to offer uniformity in your products. A well-executed pasteurization procedure not only prolongs beer's shelf life, however it makes certain that every container of your beer will certainly taste the very same, from your very first set to your last. This is particularly important for craft breweries wanting to bring in health-conscious customers who desire the carbonated goodness of soft drinks.

Tunnel pasteurizers work by bringing bottles and canisters up to their wanted temperature in phases, holding them there for long enough to exterminate the microbes that cause spoilage. They after that bring them down once again in step-by-step steps up until they reach space temperature, preserving taste profiles. By doing this, they not just stop bacteria from increasing in the item, but they likewise lower power usage by eliminating warm loss. These are the sort of efficiency gains that can accumulate promptly.

2. Reduced Waste

As even more focus is placed on eco-friendly manufacturing practices, beverage suppliers are searching for methods to minimize their waste production. Tunnel pasteurizers do a great task of this, particularly when they are developed and developed by seasoned specialists.

Tunnel pasteurizers make use of a series of sprays to heat the bottles or containers as they relocate via the device. This gets rid of the demand for a large steam container that consumes power and drainages. On top of that, Tunnel pasteurizers use a water savings system to recycle the hot water used in the home heating process, which minimizes water and sewer use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a large marketing point for craft brewers who want to prolong their items' service life and ensure uniformity between batches. Unlike flash pasteurizers, which often have problem with high degrees of carbonation, Tunnel systems can manage these effervescent mixtures without breaking a sweat (or a container).

3. Better Item Top Quality

When your drinks are effectively dealt with in Tunnel pasteurizers, they're safeguarded from unsafe microorganisms while protecting their taste accounts. This implies your brews, soft drinks, acid maintains (like fruits or acids), and wellness shots can extend their service life without shedding their trademark preference.

In order to accomplish this, tunnels include precise temperature level control and even distribution throughout their several phases. In addition, conveyor belt rates aid ensure equal treatment times for each and every bottle entering the machine. All this aids you ensure high quality results every time.

Finally, tunnels work with carbonated beverages, an expanding pattern amongst health-conscious consumers seeking carbonated choices to sweet sodas. Unlike flash pasteurizers, which can fight with high-carbonation levels, Tunnel equipments are designed to manage them.

Additionally, retrofitting tunnels with energy recovery systems reduces water usage also. By utilizing the retrieved water for air conditioning, you'll considerably cut your power consumption and greenhouse gas emissions.

4. Minimized Power Consumption

Tunnel pasteurizers are energy-intensive machines, yet you can decrease your power intake by retrofitting them with advanced environment-friendly innovation. This includes solar-powered heating elements that can operate on renewable resource sources, reducing dependence on fossil fuels and your carbon impact.

An additional wonderful feature of Tunnel pasteurizers is that they are compatible with carbonated beverages, a popular trend among today's health-conscious customers. Unlike flash pasteurizers, which occasionally deal with high-carbonation levels, Tunnel devices can take care of these fizzy mixtures with ease.

"BREWING UP THE PERFECT HOLIDAY: TOP BEER GIFTS FOR THE SEASON"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) December 5, 2023

Article Release for Brewmasters and Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for the full article: https://t.co/Z3vUL8dCpU

PRO Engineering / Manufacturing Inc.

414-362-1500

zPasteurAIzer can keep track of the effectiveness of your present Tunnel pasteurizer by estimating the built up item high quality (PU) worth for each and every set. This enables you to establish if your present temperature level control system is delivering enough warm therapy along with recognizing any kind of curved spray heads. https://www.foodprocessing.com/articles/2017/gentler-processes-for-pasteurization-and-sterilization/ can then readjust the equipment setups based on your favored PU worths, enhancing manufacturing efficiency while decreasing power intake. This is an excellent method to cut down your water usage too, straightening your service with consumer demand for ecologically liable products.

SPOILER ALERT!

7 Crucial Security Features To Think About When Picking Skid Steer Equipment

Short Article Composed By-Lake Raun

When it concerns operating skid steer tools, security must be your top concern. You might be assuming, 'However aren't skid guide equipments currently safe?' While they are developed with lots of built-in security functions, it's important to be knowledgeable about the leading 7 safety functions you ought to seek.

By recognizing these features and guaranteeing they exist in the devices you make use of, you can greatly decrease the danger of crashes and injuries. From Rollover Protection Equipment (ROPS) to rearview and sideview mirrors, these features are made to maintain you secure and shielded while running the equipment.

So, let's dive in and check out the top 7 safety features you must never forget when it comes to skid guide devices.

## Rollover Security System (ROPS).

Search for a skid guide devices with the Rollover Defense System (ROPS) to guarantee your safety. ROPS is a crucial safety function that secures you in case of a rollover accident. It contains an enhanced structure, such as a roll cage or a safety cover, that surrounds the driver's compartment.

In case of a rollover, ROPS offers a safety zone, avoiding the operator from being squashed or wounded. This safety feature is especially essential when dealing with irregular surface or in areas with a high threat of toppling.

When choosing a skid guide devices, ensure it's furnished with ROPS to reduce the threat of serious injuries or even casualties. Your security must constantly be the top concern.

## Expenses Guard.

One vital safety and security feature to think about when picking skid guide equipment is the above guard's toughness.

The above guard acts as a safety structure that guards the driver from dropping objects and particles.

It's essential to make sure that the above guard is built with high-grade materials and made to hold up against potential impacts.

A solid expenses guard not only prevents injuries but also improves the overall safety of the driver.

When operating in dangerous settings, such as building websites or farming settings, the threat of things falling from above is a consistent concern.

## Backup Alarm system.

Make certain to have a backup alarm system mounted on your skid guide devices for added security. A back-up alarm system is an essential security feature that informs people in the vicinity when the lorry is relocating opposite. This alarm emits a loud, distinct sound that serves as a warning signal.

By having Read Full Report -up alarm system, you can substantially decrease the risk of accidents and prevent accidents with pedestrians or other vehicles. It helps to develop recognition and ensure that every person stays sharp and careful when the skid guide tools is supporting.

When operating in active worksites or restricted areas, where exposure might be limited, a back-up alarm system ends up being even more essential in avoiding mishaps and keeping a safe workplace.

## Seat Belt.

Make certain that you attach your seat belt properly for maximum safety and security when running skid guide devices.

The safety belt is a crucial safety and security attribute that assists to shield you in the event of an accident or sudden stop. By wearing your safety belt, you can stop ejection from the machine, lowering the threat of serious injury and even death.

Make sure to change the seat belt to fit well across your lap and shoulder, ensuring that it isn't twisted or as well loosened.

It is essential to wear your seat belt in any way times, even if you're just running the skid steer for a short duration.

## Driver Existence System (OPS).

Are you familiar with the importance of the Operator Existence System (OPS) when running skid guide devices?

The OPS is an essential security function that assists protect against crashes and injuries. It works by calling for the operator to be seated in the machine and have their seatbelt fastened before the equipment can be operated.

If the driver leaves the seat or eliminates their seat belt, the OPS will automatically quit the engine and the hydraulic system, bringing the machine to a stop. official site makes sure that the skid guide devices stays stationary and stops it from being accidentally run by unauthorized people or in risky conditions.

The OPS offers an additional layer of defense and aids keep the security of both the operator and those working around the equipment.

## Auxiliary Hydraulic Lockout.

One vital safety attribute to consider when trying to find skid steer devices is the complementary hydraulic lockout. This function is made to prevent unintended motion of the hydraulic functions, offering an added layer of defense for both the operator and those around them.

By locking out the complementary hydraulics, it ensures that attachments or carries out can't be activated inadvertently, reducing the danger of injury or damages. This feature is particularly helpful when executing upkeep or repairs on the tools, as it stops any kind of unanticipated activity that can result in mishaps.

The supporting hydraulic lockout adds an extra degree of security and peace of mind, enabling operators to work confidently and successfully, recognizing that the device's hydraulic functions are safely locked when not being used.

## Rearview and Sideview Mirrors.

To improve safety, take into consideration equipping your skid guide equipment with rearview and sideview mirrors. These mirrors provide important exposure, allowing you to see what's occurring behind and next to your equipment. With rearview mirrors, you can easily check activities and possible dangers in your unseen area, making sure the safety and security of both on your own and others on the worksite.

Sideview mirrors, on the other hand, offer you a broader field of view, enabling you to navigate limited spaces and prevent accidents with items or various other equipment. By having actually these mirrors mounted, you can substantially minimize the dangers related to running a skid steer.

## Conclusion.

So, when it concerns skid guide tools, safety and security must always be your top concern.

The leading 7 safety features discussed in this short article, consisting of Rollover Defense System, Safety Belt, and Operator Existence System, are crucial for protecting against crashes and making sure the well-being of operators.

By investing in skid steer tools with these security attributes, you can have peace of mind knowing that you're taking the required actions to protect yourself and your employees.

Do not await a catastrophe to strike, make safety and security a concern today!

When it concerns operating skid steer tools, security must be your top concern. You might be assuming, 'However aren't skid guide equipments currently safe?' While they are developed with lots of built-in security functions, it's important to be knowledgeable about the leading 7 safety functions you ought to seek.

By recognizing these features and guaranteeing they exist in the devices you make use of, you can greatly decrease the danger of crashes and injuries. From Rollover Protection Equipment (ROPS) to rearview and sideview mirrors, these features are made to maintain you secure and shielded while running the equipment.

So, let's dive in and check out the top 7 safety features you must never forget when it comes to skid guide devices.

## Rollover Security System (ROPS).

Search for a skid guide devices with the Rollover Defense System (ROPS) to guarantee your safety. ROPS is a crucial safety function that secures you in case of a rollover accident. It contains an enhanced structure, such as a roll cage or a safety cover, that surrounds the driver's compartment.